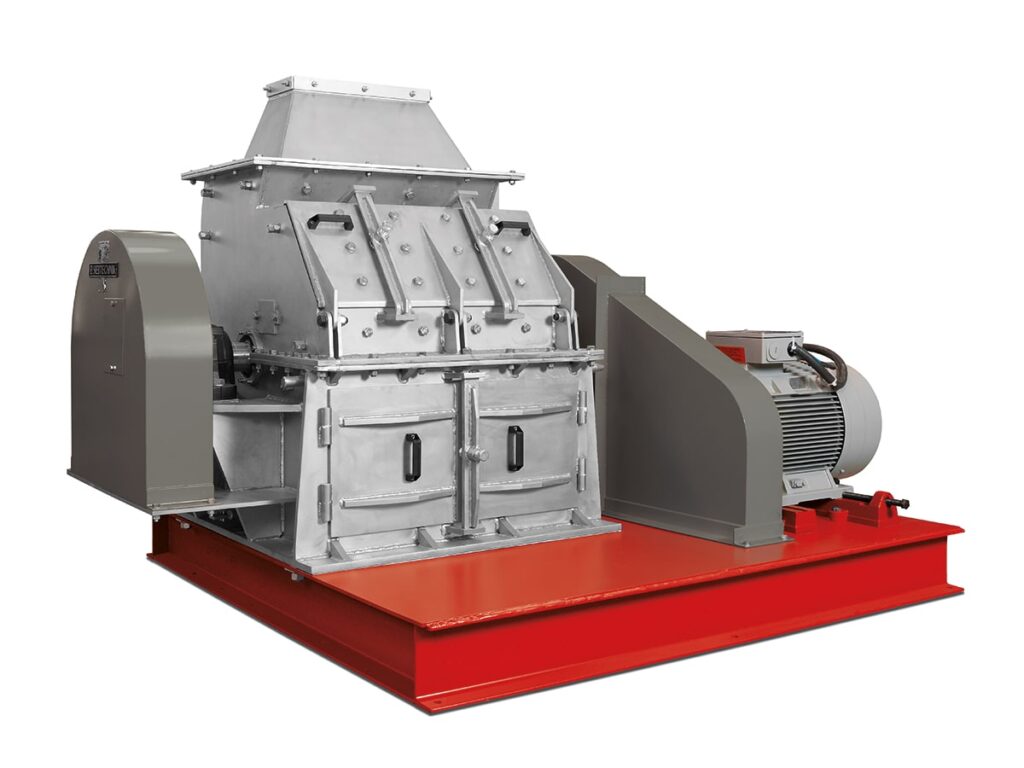

A hammer mill is a machine that comminutes materials by repeated blows of hammers mounted on a rotor. It is used for grinding raw materials for livestock feed, pet food, and aquaculture. This article will discuss how the hammer mill works, its use, and its benefits. But first, please see our reliable industrial hammer mill to suit your construction or recycling needs and budget.

How does a hammer mill work?

A hammer crusher or hammer mill crushes brittle materials. We distinguish limestone, coal, gypsum, alum, and chalk among them. The crushed materials then pass through the narrow spaces between the rotor and the grate bars, which are ground to fine particles.

Multiple constructors might get confused about the working principle of the hammer mill, but luckily, we are here to help. The hammer crusher working principle can be best explained using the single-stage hammer crusher as an example. It operates according to the following steps:

- The material to be crushed is fed into the feed hopper.

- The material is hit by hammers that are fixed to a rotating disk.

- The disk rotates at high speed, and the material is fed into it at a constant rate.

- The material is hit repeatedly until it is small enough to pass through a screen placed at the bottom of the crushing chamber.

How is a hammer mill used?

A hammer mill is a machine used to shred material into smaller pieces. These machines have many industrial uses, including grinding grain into flour, shredding paper, and crushing rocks. Hammer mills can be either electric or gas-powered, but most operate with electricity. Hammer mills work by using rotating hammers to shred the material. The hammers are made from hardened steel and are very sharp. The shredded material is then ejected from the machine at high speed.

Hammer mills can be used for various applications, including recycling, agriculture, and wood processing. Recycling centers use hammer mills to grind glass, plastic, and metal into smaller pieces. Farmers often use these machines to grind corn into livestock feed. Meanwhile, wood processors use hammer mills to create sawdust for animal bedding and mulch for landscaping projects.

What are the benefits of hammer mills?

Hammer mills are size-reduction equipment used to shred or crush materials into smaller pieces. It’s used in the agricultural and food processing industries to grind fragments into smaller pieces or particles. The machine consists of a screen, hammers, a flywheel, a rotor, and a feed hopper. The benefits of using a hammer mill include:

- Increased product quality: Hammer mills produce uniform particle sizes, improving the end product’s quality.

- Increased throughput: A hammer mill can process a high volume of material in a short amount of time.

- Reduced operating costs: Hammer mills are less expensive to operate than other types of size reduction equipment.

- Flexibility: Hammer mills can process various materials, including grain, spices, herbs, and more.

- Reduced energy consumption: Hammer mills use less energy than other types of size reduction equipment.

What materials can hammer mills process?

Different hammer mills can process various materials, including grain, wood, paper, and more. But which materials are the most commonly processed by hammer mills?

Grain: Hammer mills are used for crushing grain into smaller pieces that can be used for animal feed or as flour. Common grains processed by hammer mills include corn, wheat, barley, and rye.

Wood: Hammer mills can also process wood chips, sawdust, and other biomass materials. By processing wood in a hammer mill, you can create wood shavings or sawdust that can be used as animal bedding or as fuel for pellet stoves or boilers.

Paper: Hammer mills sometimes recycle old newspapers and other paper products. The paper is shredded into small pieces that can be used as mulch or composted.

How to choose the best hammer mill for my needs?

There are many different types of hammer mills on the market. How do you know which one is right for your requirements? Here are a few things to consider when choosing the best hammer mill for your needs:

- The size of the unit. A larger unit may be more expensive, but it can handle more material at once. This is important if you have a large operation with a lot of material to process.

- The type of material you need to process. Some materials are more difficult to process than others. If you are processing many tough materials, you will need a robust machine that can handle the workload.

- Your budget. As with anything, you get what you pay for with a hammer mill. But, there are some quality units available at an affordable price point.